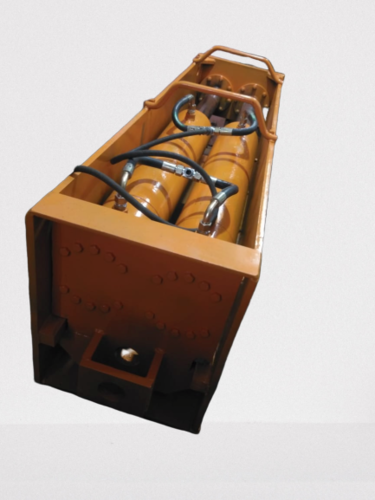

RCC Pipe Blasting Machine

Price 25000-30000 INR/ Piece

MOQ : 1 Piece

RCC Pipe Blasting Machine Specification

- Lifting Height

- 2.5 m

- Surface

- Polished

- Motor Power

- 15 HP

- Lifting Speed

- 8 m/min

- Product Type

- RCC Pipe Blasting Machine

- General Use

- Surface cleaning and preparation of RCC pipes

- Material

- Mild Steel

- Type

- Automatic Blasting Machine

- Capacity

- Up to 300 pipes per day

- Weight (kg)

- 4800 kg

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Controlled

- Cooling System

- Air Cooling

- Method

- Shot Blasting

- Voltage

- 415 V / 50 Hz

- Dimension (L*W*H)

- 4200 x 1850 x 2500 mm

- Feature

- High efficiency, Low maintenance, Robust Construction

- Color

- Blue / Grey

- Conveyor Type

- Roller Conveyor

- Noise Level

- <85 dB

- Working Diameter Range

- 300 mm to 2500 mm

- Abrasive Flow Rate

- 200 kg/min

- Dust Collector Type

- Cartridge Filter

- Chamber Construction

- Fully enclosed with wear-resistant lining

- Paint Requirement After Blasting

- Surface ready for direct coating

- Door Type

- Auto/Manual Sliding Door Option

- Blast Wheel Quantity

- 2

- Loading System

- Hydraulic or Manual Loading

RCC Pipe Blasting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About RCC Pipe Blasting Machine

R C C Pipe Blasting is offered by us in a wide assortment of technical specifications as required by the clients depending on the need of the application. It is manufactured using a rigid aluminum material to provide enough stability and strength to the machine. It is equipped with several technical accessories such as PID controller, pipe fittings, clamps, PU seals etc. It is widely used in industrial areas such as in construction, pipeline layering, pipe trenches etc for the welding of pipes. This machine is finished with a paint coating so that it can withstand corrosion, rust, and heat. Also, the R C C Pipe Blasting is checked by our quality team to ensure its optimal functionality and flawless design.Superior Surface Preparation for RCC Pipes

This automatic blasting machine ensures RCC pipes are meticulously cleaned and perfectly prepared for direct coating. Its dual blast wheels and high abrasive flow guarantee thorough removal of contaminants, delivering a consistently polished finish suitable for immediate painting. Advanced automation and robust construction facilitate efficient daily throughput of up to 300 pipes with minimal manual intervention.

Low Maintenance, High Performance

Engineered with an air-cooling system and wear-resistant lined chamber, this machine provides outstanding durability and minimal upkeep over extended usage. The automated PLC control system and cartridge filter dust collector work together to keep maintenance requirements low, enhancing productivity while maintaining a safe work environment.

Versatile and User-Friendly Design

Featuring both hydraulic and manual loading systems along with auto/manual sliding door options, this blasting machine adapts seamlessly to different operational needs. The user can control the process with precision, ensuring smooth, safe, and efficient handling of pipes across the full diameter spectrum. Its robust build and intelligent conveyor system make it a reliable asset for manufacturers and suppliers in India.

FAQs of RCC Pipe Blasting Machine:

Q: How does the RCC Pipe Blasting Machine improve the surface preparation of pipes?

A: The machine employs two high-efficiency blast wheels and a powerful abrasive stream to remove rust, contaminants, and residues from RCC pipe surfaces. This deep cleaning ensures the pipe surfaces are perfectly ready for direct painting or coating without additional preparation steps.Q: What working diameter range can this blasting machine handle?

A: It accommodates RCC pipes ranging from 300 mm to 2500 mm in diameter, making it versatile for varying pipe sizes commonly used in construction and infrastructure projects.Q: When is the ideal stage to use this machine during pipe manufacturing?

A: The ideal time to use the blasting machine is after pipe casting and curing, but before applying any coatings or paints. This optimizes coating adhesion and ensures longevity of the protective layer.Q: Where is the best place to install the RCC Pipe Blasting Machine?

A: It is best installed in manufacturing facilities or supplier workshops where RCC pipes are produced or prepared for distribution. The machine requires a dedicated space measuring at least 4200 x 1850 x 2500 mm for proper operation and safety.Q: What is the process flow of pipe blasting in this machine?

A: Pipes are placed on a roller conveyor (hydraulically or manually), then moved into the fully enclosed chamber. The machine, controlled by a PLC system, automatically blasts the surfaces with abrasivethanks to two blast wheelswhile the cartridge filter system manages dust. The finished pipes emerge ready for immediate coating.Q: How does the dust collector system enhance usage?

A: The cartridge filter-type dust collector effectively captures and filters abrasive particles and dust generated during blasting. This maintains a cleaner, safer work environment and reduces maintenance needs for the machine and surrounding workspace.Q: What key benefits does the RCC Pipe Blasting Machine offer manufacturers and suppliers?

A: Key benefits include high daily capacity (up to 300 pipes), reduced manual labor due to automation, consistently high-quality surface preparation, low noise operation, minimized maintenance, and a robust, wear-resistant chamber for long-term durability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

MI TECH HYDRAULICS

Delhi, India

Delhi, India

C-178, Mayapuri Industrial Area Phase 2, Near TVS Service Centre, New Delhi - 110064, India

Phone :08045804330

|

Sabu Bose

Mobile Number: 9811479582

Mobile Number: 9811479582

|

MI TECH HYDRAULICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry